Se.co.pack integrates the supply of quality stretch film with technical consulting service on the packaging process; the goal is to ensure the highest possible level of service, to generate technical, economic, and organizational value for the Customer.

Optimize the process

Efficient use of the supplied film wrapper, effectively employing the available wrapping options and programs

Correct application of stretch film, with the development of a customized wrapping process to ensure product safety

Reduced production downtime by increasing the range of each roll and decreasing reel changes

Reduce the stretch film used

Decrease in packaging residues and waste: the less stretch film is used, the less residue will be left to be handled in the post-consumer phase

Reduction in the amount of stretch film to be produced, transported, and stored, achieved by decreasing the amount of plastic used per package

Improving security

Creation of homogeneous and stable palletized units throughout the distribution chain

Reduced damage to goods, with a significant reduction in complaints, savings on replacement costs of damaged goods, and a positive impact on corporate image

Reducing risks to operators when handling and transporting goods

Customizing stretch film

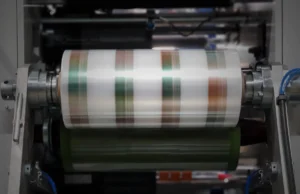

Promotion of client's brand identity by flexographic printing of stretch film

Production of coils with specific dimensional characteristics, suitable for each type of machinery

Manage orders and shipments quickly

Reduced packaging stock at the end user due to the wide availability of products in our warehouse, always ready for shipment

Reduced procurement time through efficient order picking and transportation arrangements

Reduce costs

Reduction in the annual cost of purchasing packaging achieved by optimizing the process and reducing the amount of stretch film needed.

Reduction in taxes and environmental contribution (CONAI) due to the decrease in the total weight of packaging used.

Creating value means ensuring the security of goods by using a minimum amount of stretch film

At the lowest possible cost per palletized unit.

And provide the most suitable product at the time when the customer needs it.